We provide repair and maintenance services for industrial equipment, ensuring optimal operation and extending its service life through precise diagnostics and effective, efficient solutions.

In mining, operational availability is paramount. The strategic repair of mining components makes the difference between wear and sustained productivity.

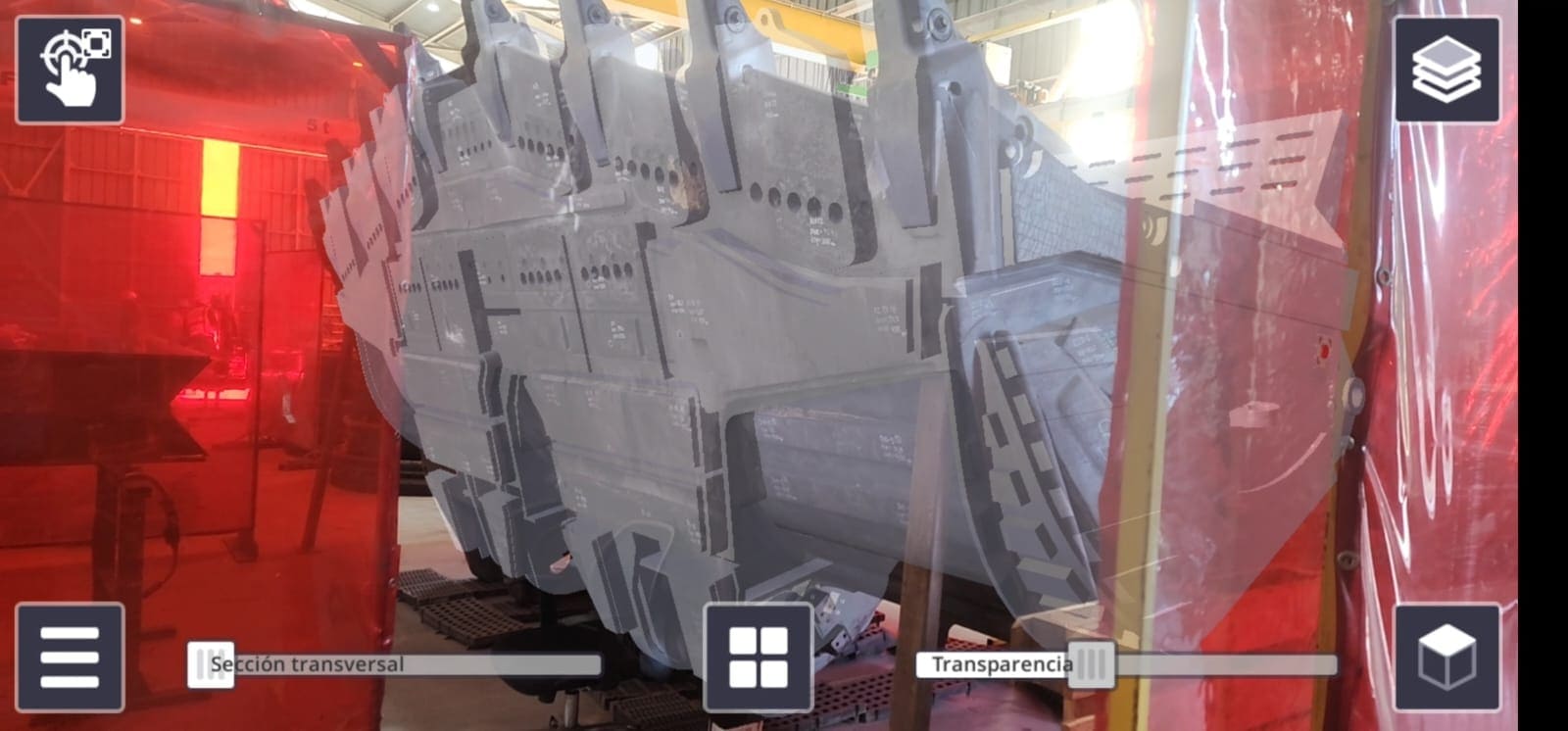

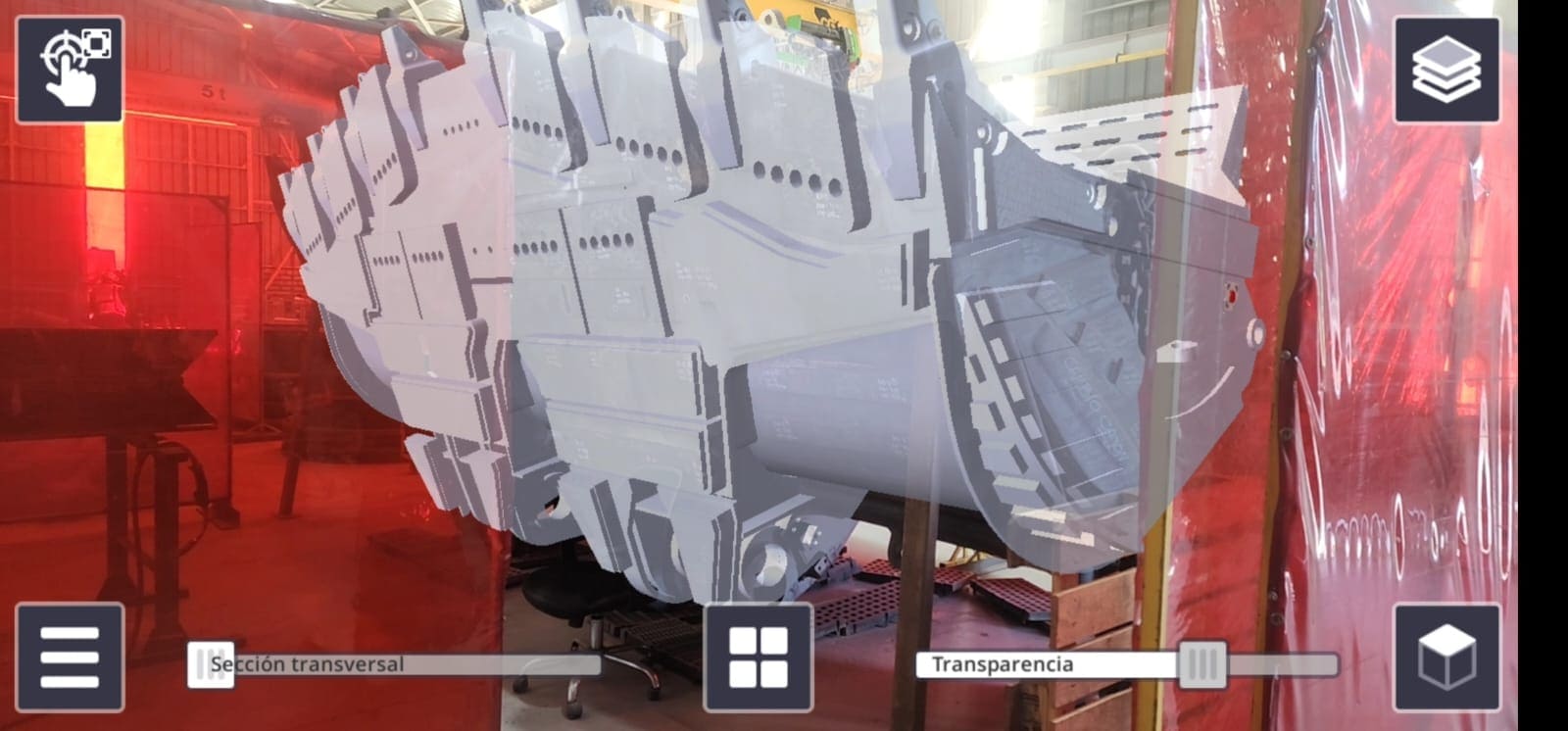

At CG Kofilman, we transform every component into a key piece for our clients' operational continuity, with a robust and efficient technical process.

As a Trinorma-certified company, we have standardized processes for each of our clients' components, with the following key stages for a process:

Our installed capacity allows us to repair all types of components, without restrictions.

SCREENS, CHUTES, BINS, LARGE-SIZED DUCTS, AND LINERS.

Comprehensive repair, with or without supply of spare parts. We have our own line of linings: rubber, rubber-ceramic, silicon carbide, and polyurethane.

Includes special painting schemes and no-load operational tests.

A quality dossier is provided.

Comprehensive repair with or without spare parts provision, including lip for auxiliary equipment.

We work with high-quality steels to ensure the longevity of our components, always with documented evidence of improvements in design, allowing us not only to repair but rather to increase the components' lifespan.

Comprehensive structural repair service for maintenance, including large-scale components such as aprons and agitator shafts. The service includes reverse engineering, load certification, engineering calculations, balancing, and delivery of a complete quality dossier.

SCREENS, CHUTES, BINS, LARGE-SIZED DUCTS, AND LINERS.

Comprehensive repair, with or without supply of spare parts. We have our own line of linings: rubber, rubber-ceramic, silicon carbide, and polyurethane.

Includes special painting schemes and no-load operational tests.

A quality dossier is provided.

Comprehensive repair with or without spare parts provision, including lip for auxiliary equipment.

We work with high-quality steels to ensure the longevity of our components, always with documented evidence of improvements in design, allowing us not only to repair but rather to increase the components' lifespan.

Comprehensive structural repair service for maintenance, including large-scale components such as aprons and agitator shafts. The service includes reverse engineering, load certification, engineering calculations, balancing, and delivery of a complete quality dossier.

Contact us and power up your operations with our expert team.